top of page

Aerial platform truck industrial design

We proposed a design solution for the aerial platform truck used in utility pole repair. Traditional maintenance vehicles often lack off-road capabilities and considerations for operational workflows. We designed a safer and more efficient solution for the operators through interviews and observation.

Year: 07/2015 - 05/2016

Location: Taiwan

Type: Capstone project

Group work: with Chen ming-hsun Supervisor: Chen wen-zhi

PROJECT GOAL & WHAT WE DO

Research

In Taiwan, cherry picker often use trucks, and are equipped with brackets and lift arms.

1. They cannot adapt to the mountainous terrain of Taiwan.

2. Even the accident that the whole car slipped down the hillside was reported.

Interview: Persona

We interviewed the operators and observed the on-site operational processes, discovering that as the members are younger, they prefer aerial platform trucks instead of climbing poles.

Current vehicle

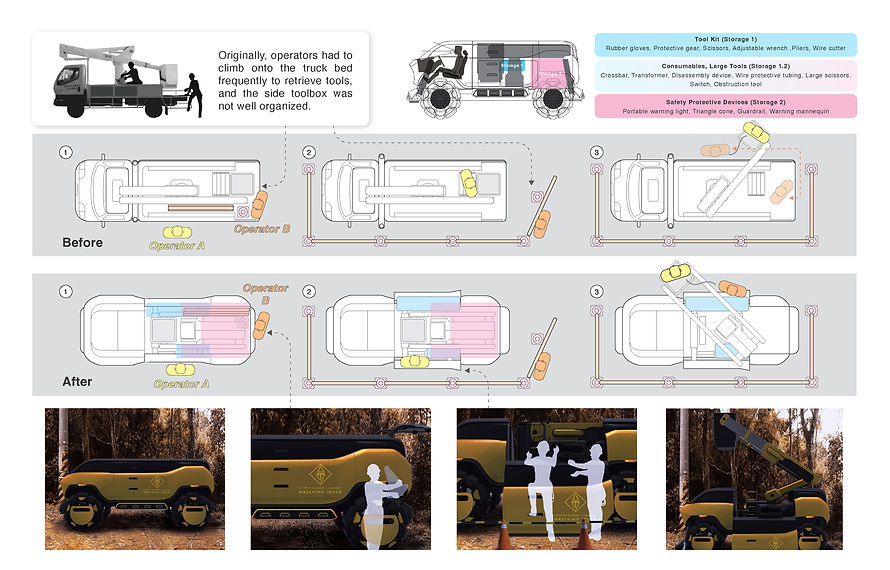

In Taiwan, high-altitude operation vehicles are typically retrofitted from small trucks, lacking off-road capability. There are also issues with space utilization, as workers often need to climb onto the truck bed to access tools repeatedly.

WORKING PROCESS

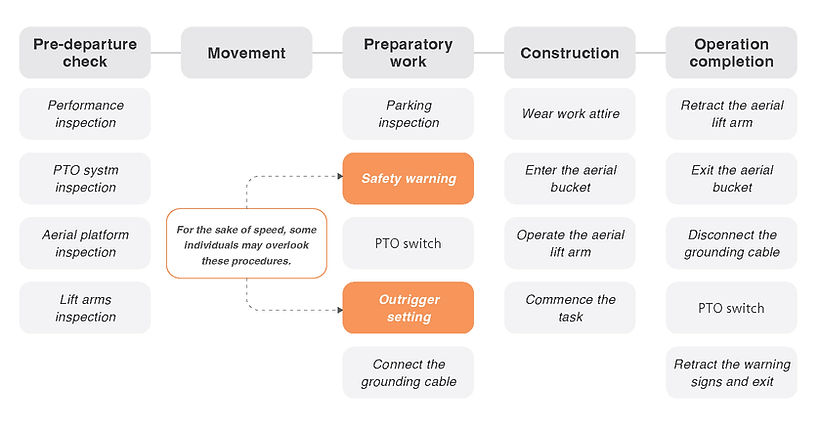

Since most aerial work platforms in Taiwan are modified from trucks, operators can still manipulate the elevated boom even when operators don't deploy outriggers. In the pursuit of efficiency, many operators avoid setting up the outriggers, posing a significant safety risk. Safety is the top priority and an urgent issue that needs to be addressed.

IDEA SKETCH & DEVELOPMENT

(Here are all my sketches)

WORKFLOW COMPARISON

Upon arrival at the site, assess the surroundings.

Retrieve the safety warning guardrail from the rear storage compartment and place it around the work area.

Retrieve equipment from the side storage, and use the side steps and ladder to enter the aerial bucket.

Once in the bucket, operate the aerial lift arm to the desired position for high-altitude work.

CAD (Rhino)

We used Rhino for 3D modeling and PLA 3D printing with surface finishing. In the 3D modeling process, I was responsible for the main structural design and the surfaces of the rear end and windows. My team members handled the front end and body contour lines. After completion, we reviewed all the surface details together.

My 3D rendering

Model making

Final model

bottom of page